What is a Megger Test and why is it necessary?

A Megger Test, also known as an insulation resistance test, is a diagnostic method used to measure the electrical resistance of insulation under high voltage conditions. This test is crucial for assessing the condition of electrical insulation in wiring, motors, and other equipment to ensure operational safety and efficiency. It helps in identifying deteriorated insulation that could lead to operational failures or hazardous situations.

The Megger Test involves applying a high DC voltage between an electrical conductor and its insulation barrier, then measuring the current that leaks through the insulation. The test can pinpoint areas where insulation may be weak or damaged. It requires a specialized device known as a Megger, which generates the high voltage and measures leakage current.

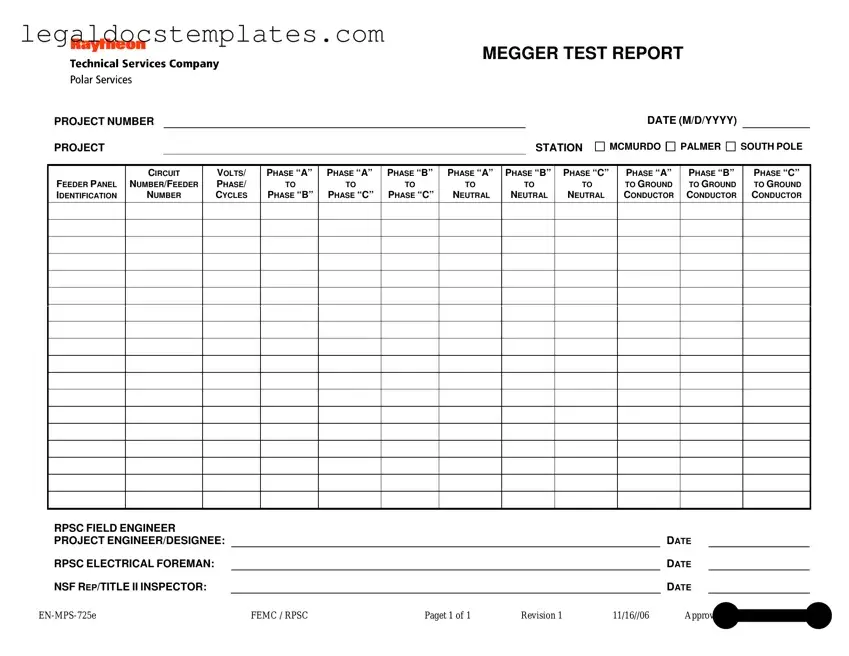

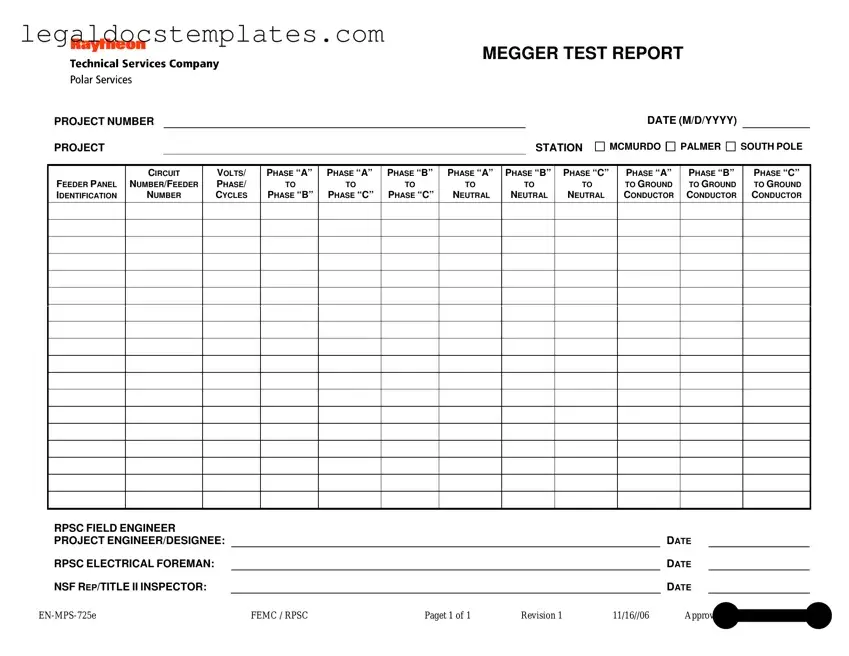

The Megger Test Report contains crucial information about the electrical system being tested, including:

-

Project Number and Station indicating the specific project and location

-

Date of the test

-

Identification details for feeder panels and circuits

-

Voltage, phase, and cycle specifics for the electrical system

-

Insulation resistance measurements between different phases, to neutral, and to ground conductors

-

Signatures of the responsible engineers and inspectors indicating the test has been reviewed and approved.

What does the RPSC field engineer role entail?

The RPSC (Raytheon Polar Services Company) field engineer is responsible for overseeing the testing process, ensuring all procedures are followed correctly, and verifying that the electrical systems meet required safety and quality standards. This engineer also plays a critical role in analyzing the test results and proposing any necessary corrective actions.

Multiple signatures ensure that the test has been conducted properly and that the results have been accurately recorded and reviewed by all relevant parties. It includes the signatures of the RPSC field engineer, the project engineer/designee, electrical foreman, and the National Science Foundation (NSF) representative or Title II inspector. This collaborative review process guarantees the integrity and reliability of the test and its findings.

What do the different insulation resistance measurements indicate?

Insulation resistance measurements are made between each phase, neutral, and ground conductors to assess the quality of insulation across different parts of the electrical system. Measurements are expressed in megohms, and higher readings generally indicate better insulation quality. Specific values help identify potential issues:

-

Phase-to-Phase measurements evaluate insulation condition between different phases.

-

Phase-to-Neutral and Phase-to-Ground measurements assess the insulation quality between live conductors and non-current carrying parts.

The precise interpretation of these values depends on the standards and benchmarks established for the specific equipment or installation being tested.

Can a Megger Test damage sensitive electrical equipment?

While the Megger Test involves applying high voltage, it is generally safe for most electrical equipment. However, certain sensitive equipment may require specific precautions or a modified testing approach to prevent damage. It is important to consult the equipment’s manufacturer guidelines and a qualified electrician to determine the safest testing procedures.

How often should Megger Tests be conducted?

The frequency of Megger Tests depends on several factors, including the type of equipment, its age, usage conditions, and the environment in which it operates. Regular testing is recommended as part of a preventive maintenance program. For many installations, conducting a test annually or as part of a routine inspection schedule is sufficient to ensure ongoing safety and performance.

What does the NSF Rep/Title II Inspector do?

The NSF Rep/Title II Inspector is responsible for ensuring that the testing meets the standards and regulations set forth by the National Science Foundation. Their role is critical in projects requiring adherence to specific governmental or industry standards, providing an additional layer of oversight and verification that electrical systems are safe and compliant with relevant guidelines.

How can discrepancies in the Megger Test results be addressed?

If discrepancies or unexpectedly low insulation resistance values are found, it’s critical to investigate the cause. This might involve:

-

Re-examining the electrical system for any signs of damage or deterioration.

-

Conducting additional tests to isolate the issue.

-

Implementing repairs or updates to the electrical insulation as necessary.

Addressing these discrepancies promptly helps maintain safety and efficiency within the electrical system.

PALMER

PALMER

SOUTH POLE

SOUTH POLE